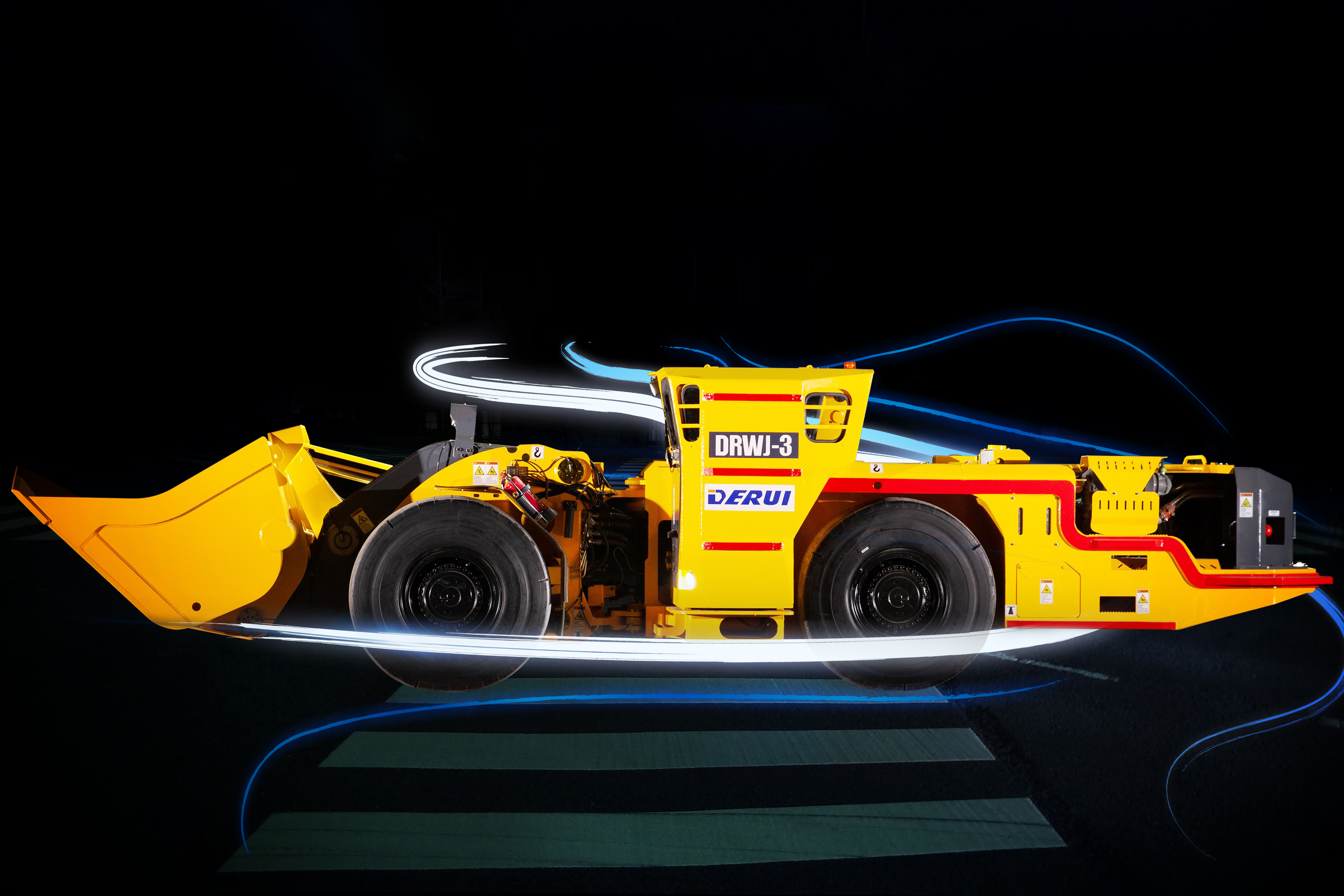

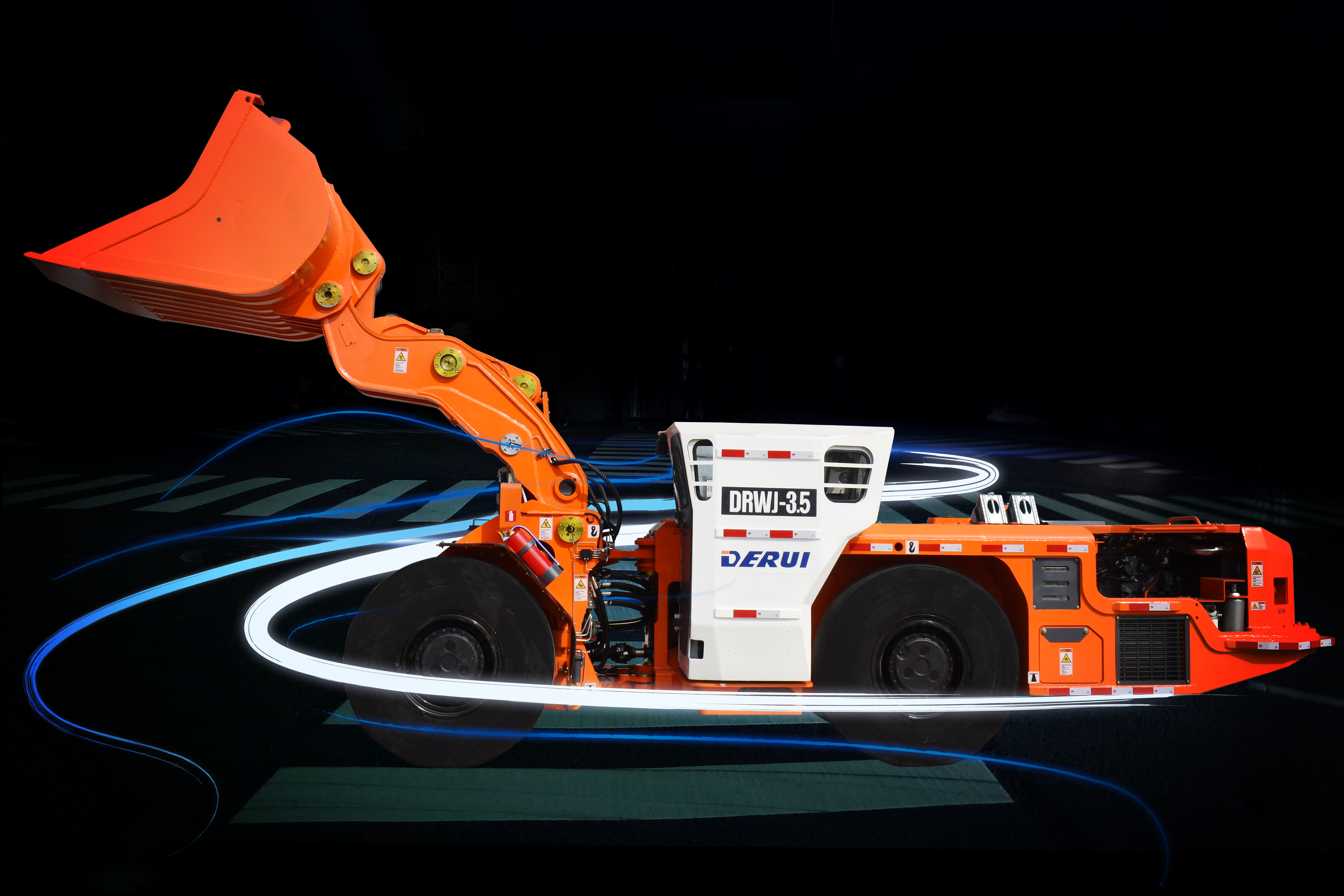

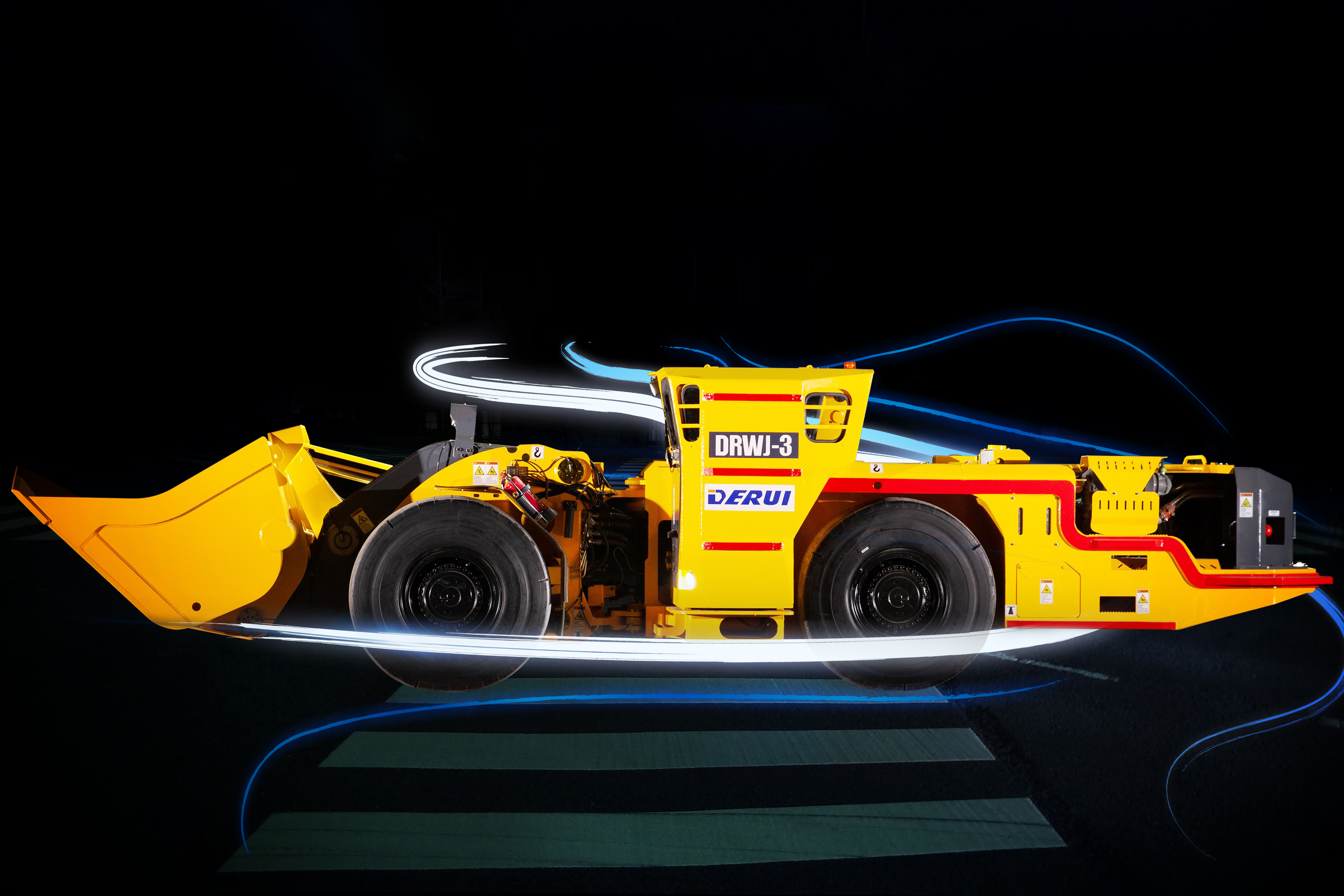

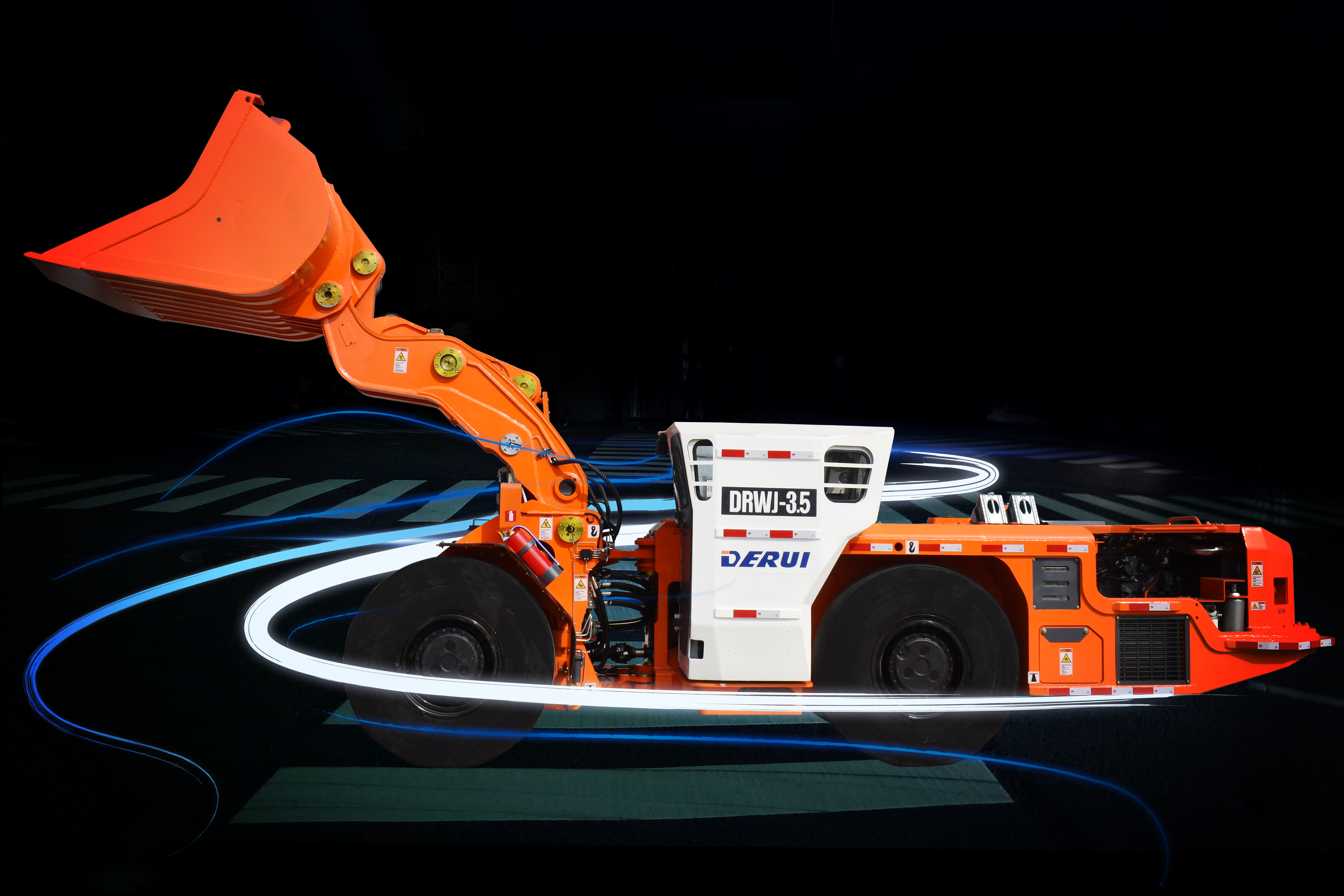

The DRWJ-3 is a robust 6.5 metric tonne LHD (latest released model DRWJ-3.5 is with 6.8 Ton payload and 3.5m³ bucket). It is a diesel-powered heavy-duty machine intended for the most demanding mine environments. The DRWJ-3 is designed for small- to medium-size openings for load-and-carry applications.

The rugged powertrain and high lifting design simplifies underground truck loading. the DRWJ-3.5 currently offers the largest bucket, most powerful engine and best climb performance in its class.

The LHD carries 6.5-6.8 tonnes or 3.0-3.5 m3. It is 9.200 mm long in driving position, 2.355 mm wide at the bucket and 2.255 mm high at the cab when fully loaded. This makes the DRWJ-3 suitable for narrow vein operations.

The DRWJ-3 and DRWJ-3.5 features Z-bar linkage and a reinforced boom design for superior breakout force enabling optimal penetration into the pile and fast bucket filling.

Loading 20-to-22-tonne trucks is also easier with excellent lift capabilities. The Z-bar linkage, generating powerful breakout force and a refined attack angle for enhanced material penetration.

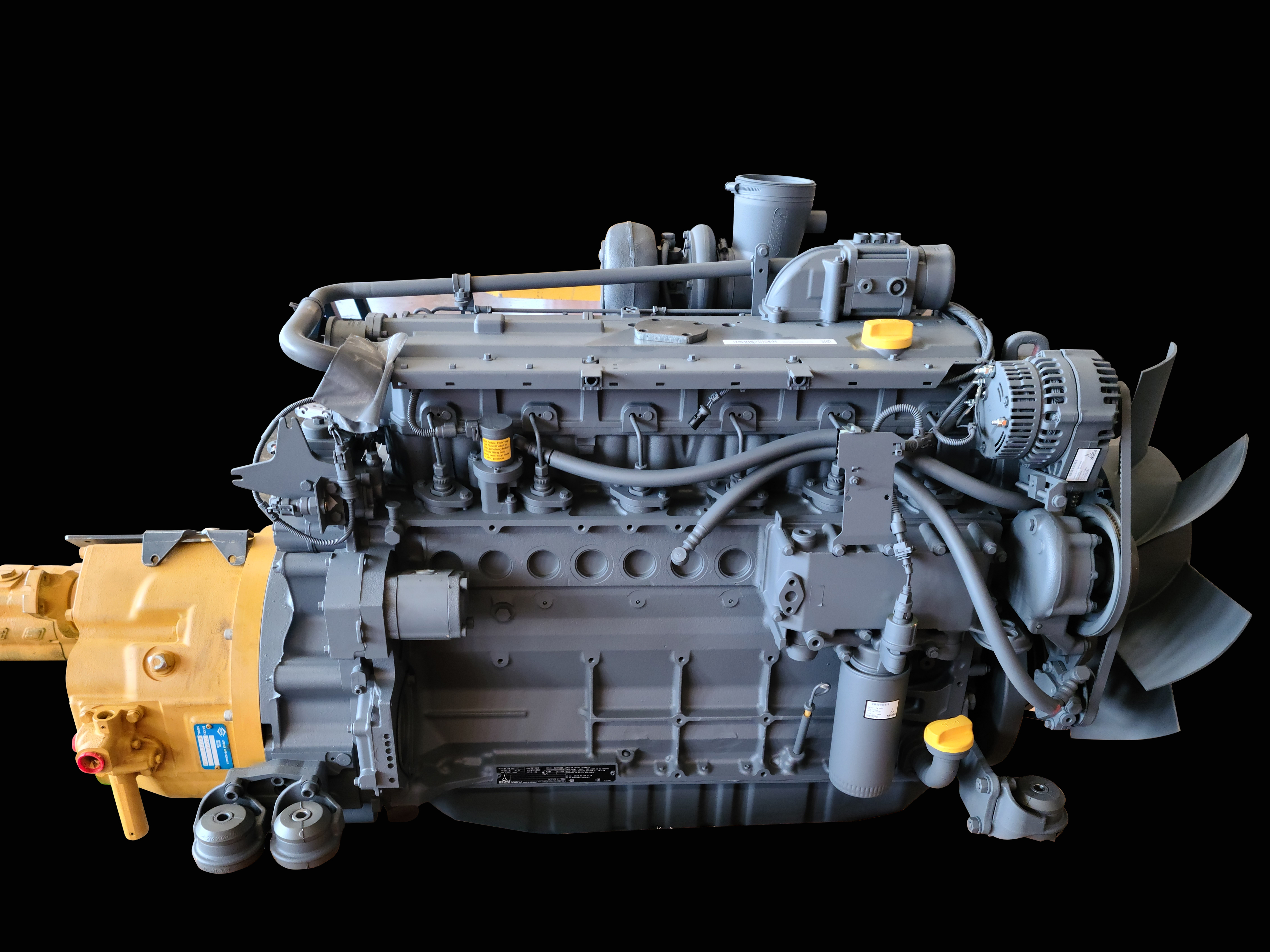

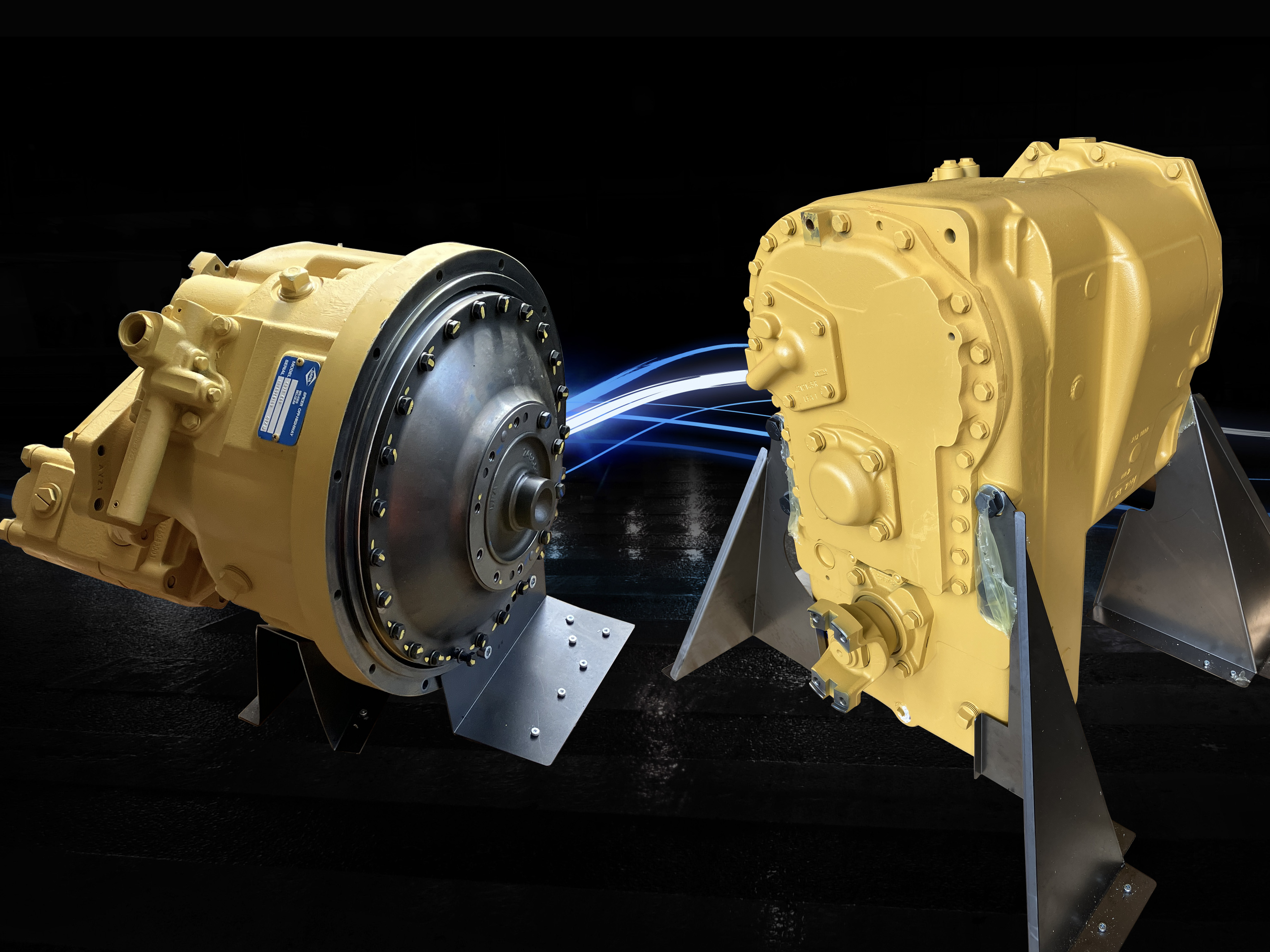

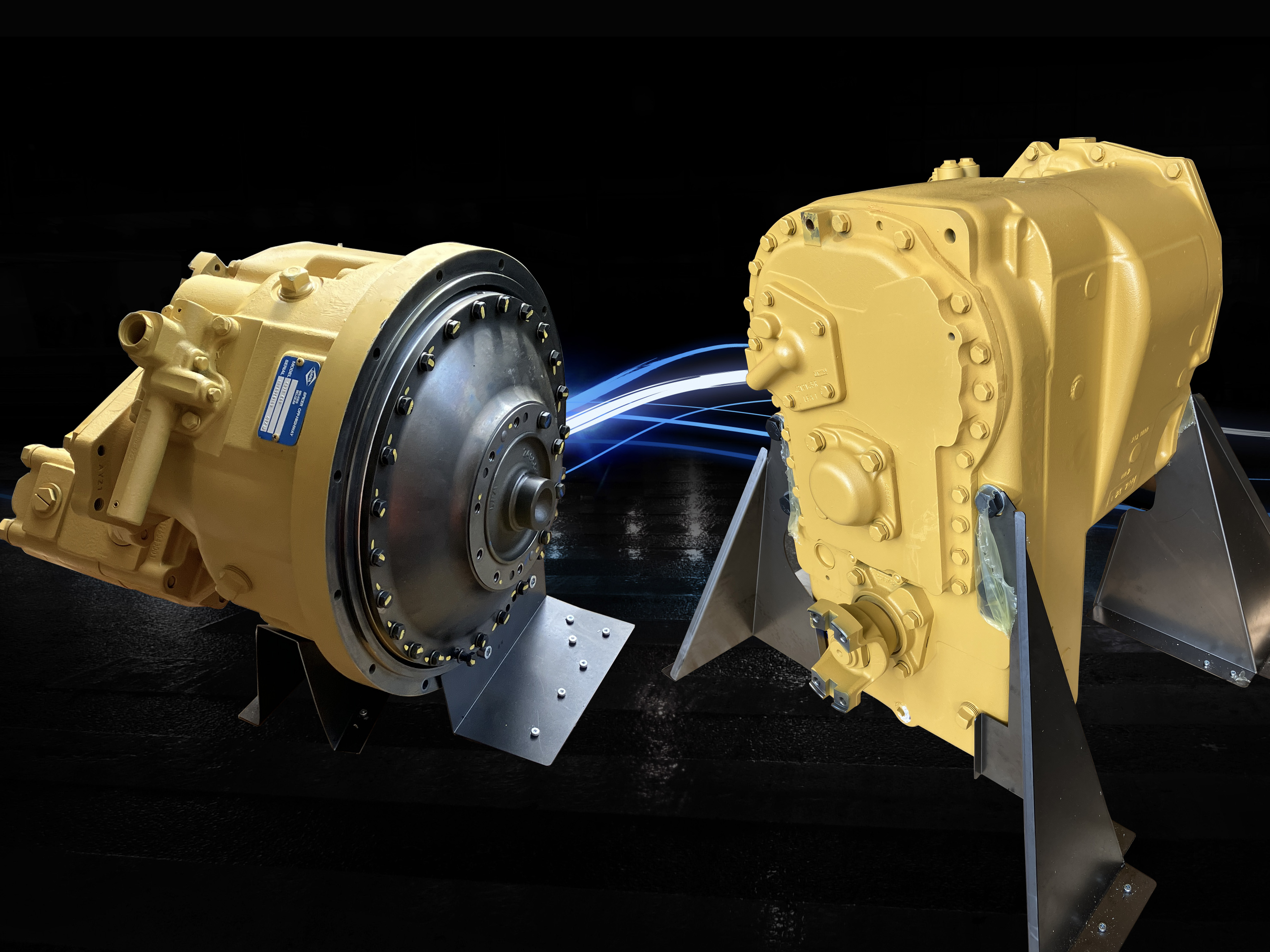

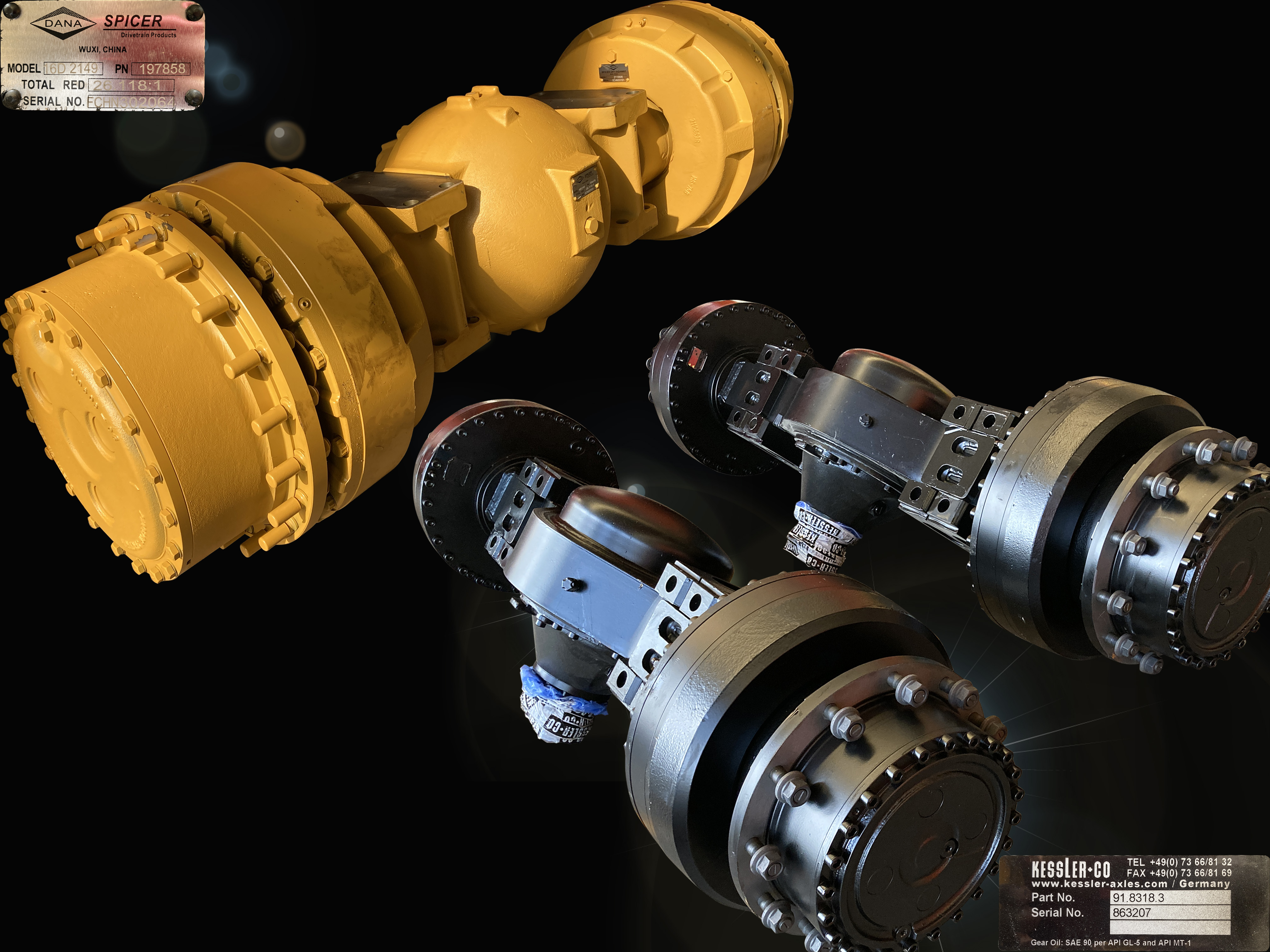

A high power-to-weight ratio complemented by a fully integrated powertrain consist of DANA transmission and torque converter, automatically matching the gear selection to the load - producing a high tractive effort without wheel spin.High capacity torque converter delivers more power to the wheels for superior power train efficiency.

A high power-to-weight ratio complemented by a fully integrated powertrain consist of DANA transmission and torque converter, automatically matching the gear selection to the load - producing a high tractive effort without wheel spin.High capacity torque converter delivers more power to the wheels for superior power train efficiency.

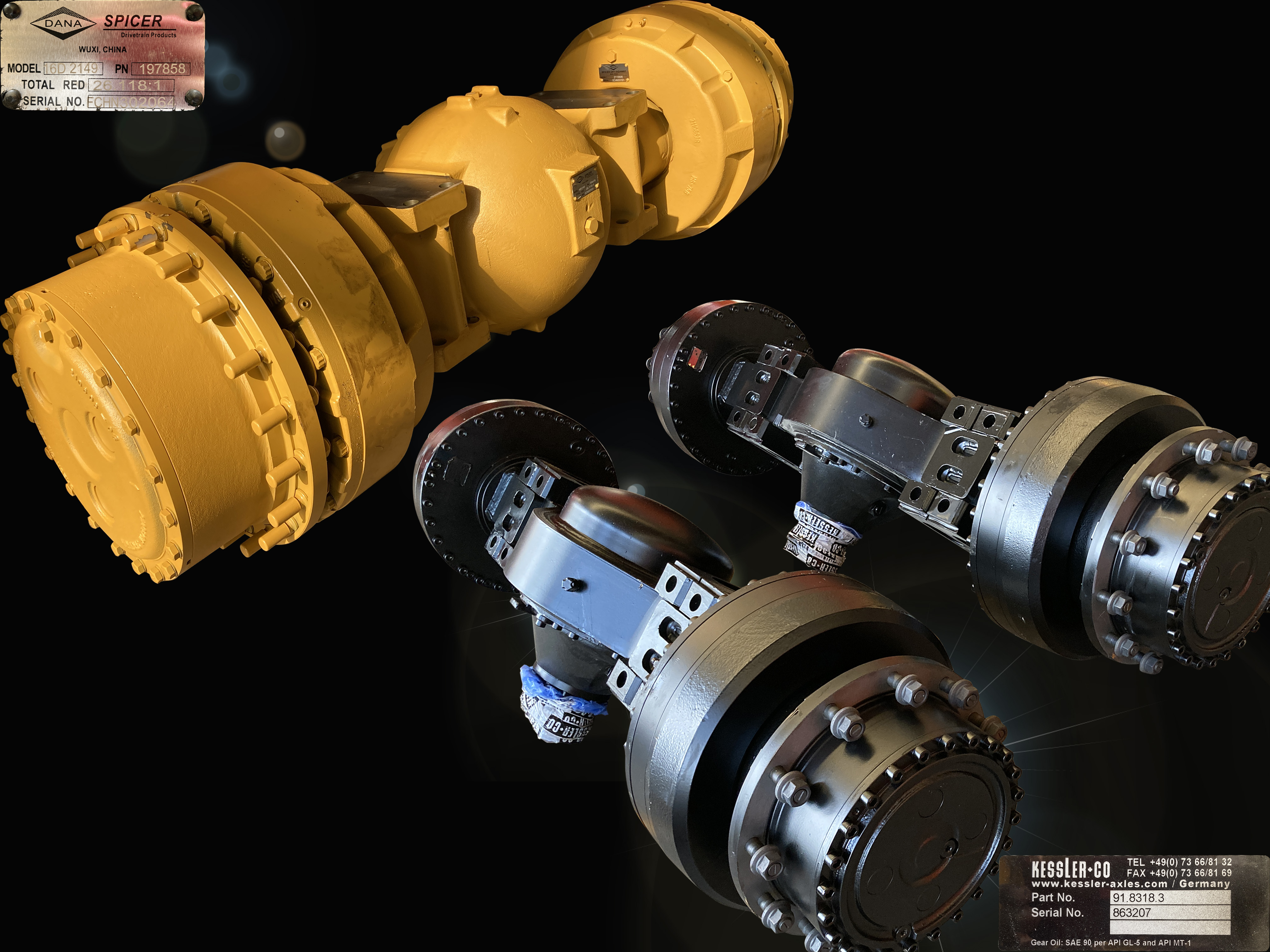

Various drive axles options, fit the needs of customers with diversified demands. Heavy duty axles are built rugged for long-life in the most demanding environments. Oscillating Rear Axle. Oscillating rear axle ensures four-wheel ground contact for maximum traction and stability at all times. No spin rear differential on KESSLER D91 axles can reduce tire wear and maximizes traction.

Various drive axles options, fit the needs of customers with diversified demands. Heavy duty axles are built rugged for long-life in the most demanding environments. Oscillating Rear Axle. Oscillating rear axle ensures four-wheel ground contact for maximum traction and stability at all times. No spin rear differential on KESSLER D91 axles can reduce tire wear and maximizes traction.

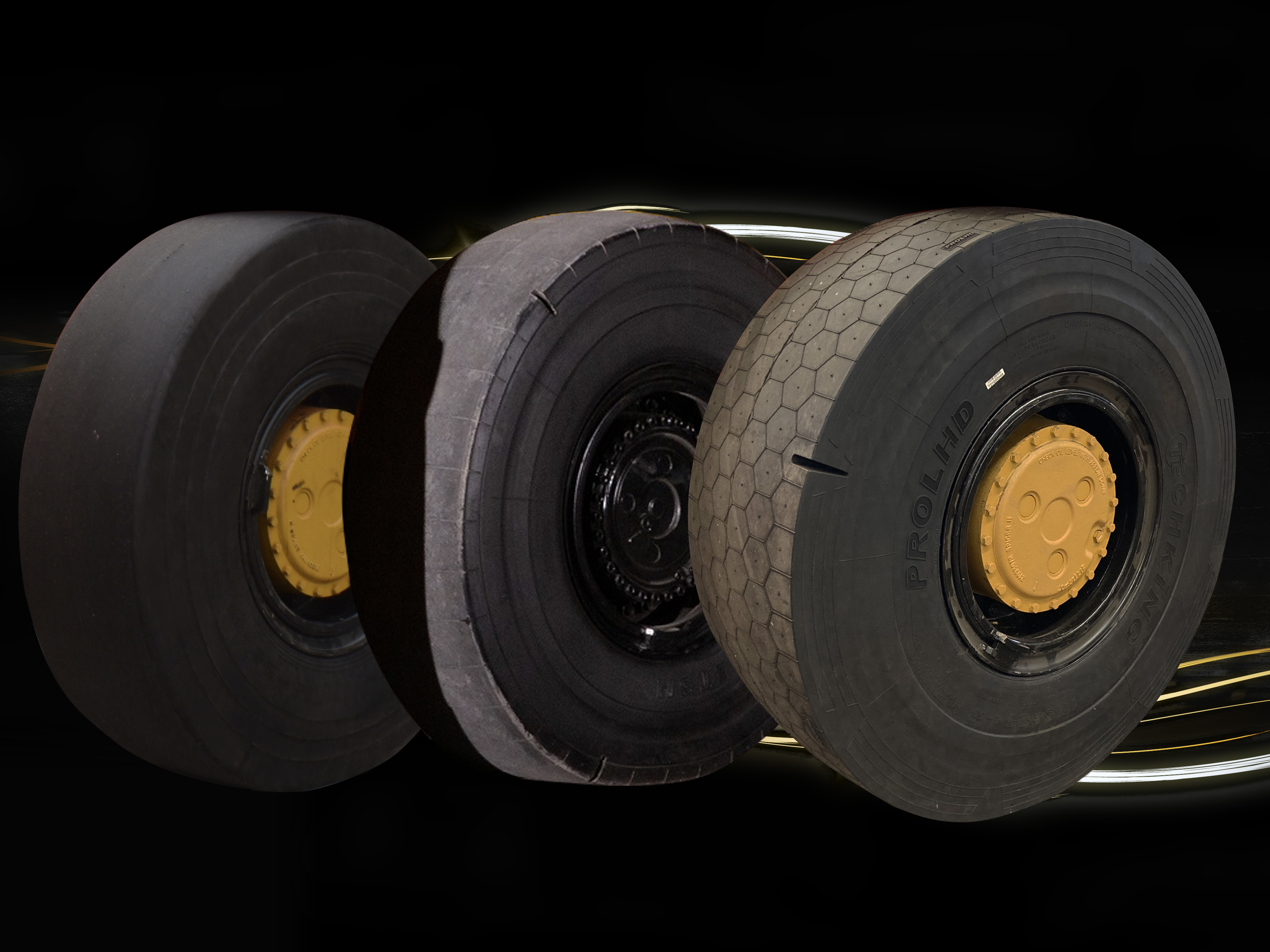

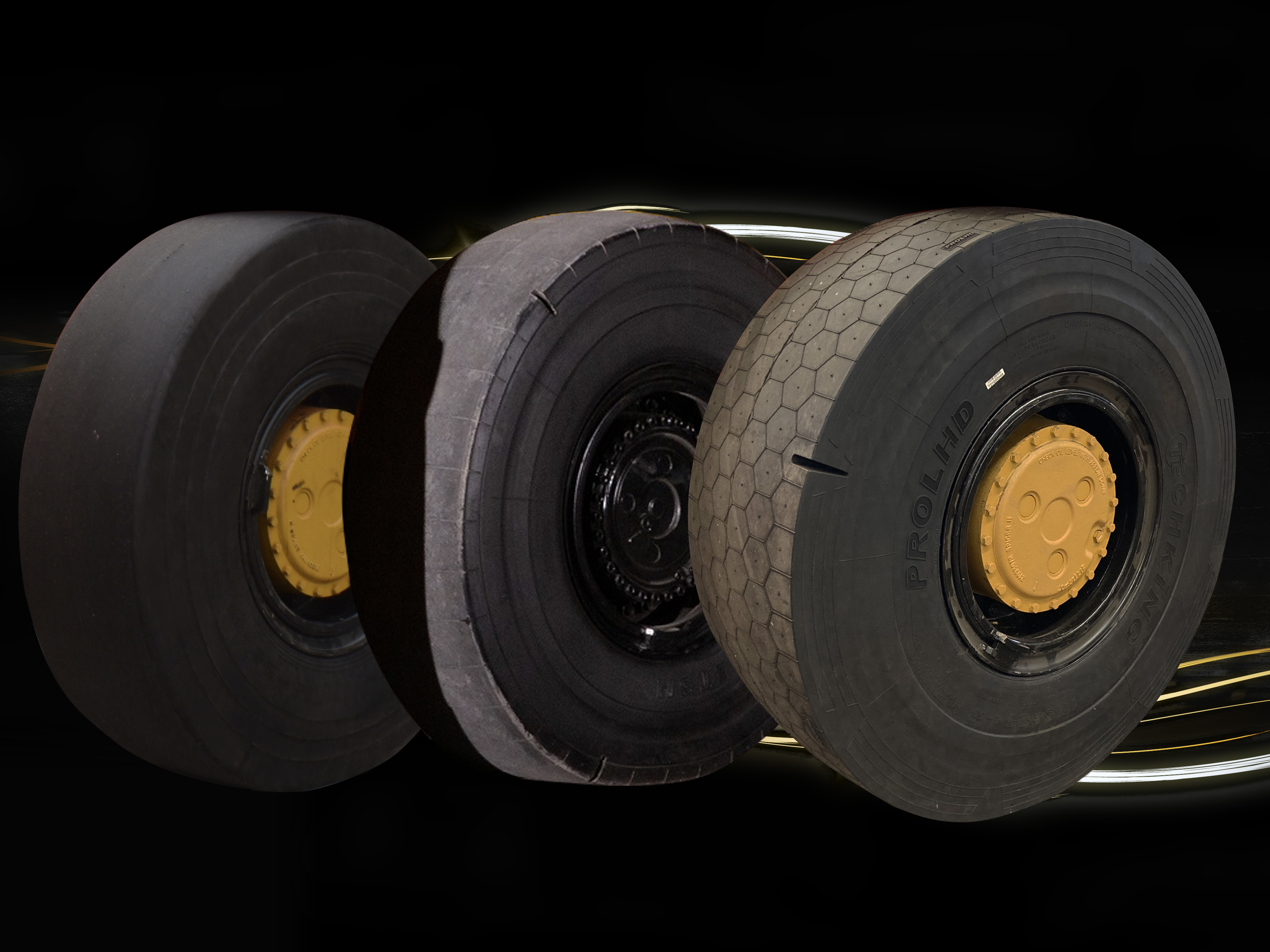

Various tires options, Bias L5S (with tube or tubeless) or Radial, fit the needs of customers with diversified demands.

Various tires options, Bias L5S (with tube or tubeless) or Radial, fit the needs of customers with diversified demands.

Steering System Single, Large Bore, Double Acting Cylinder;Designed for Excellent Steering Response at all Engine Speeds;Steering Neutralizer Integrated in the multi-way valves center.

Steering System Single, Large Bore, Double Acting Cylinder;Designed for Excellent Steering Response at all Engine Speeds;Steering Neutralizer Integrated in the multi-way valves center.

Combines directional selection, gear selection and steering into a single lever for maximum responsiveness. Simple side-to-side motion turns machine right or left. Transmission shifting (forward/ neutral/reverse) is controlled using a three position rocker switch. The thumb buttons operated upshift and down.

Combines directional selection, gear selection and steering into a single lever for maximum responsiveness. Simple side-to-side motion turns machine right or left. Transmission shifting (forward/ neutral/reverse) is controlled using a three position rocker switch. The thumb buttons operated upshift and down.

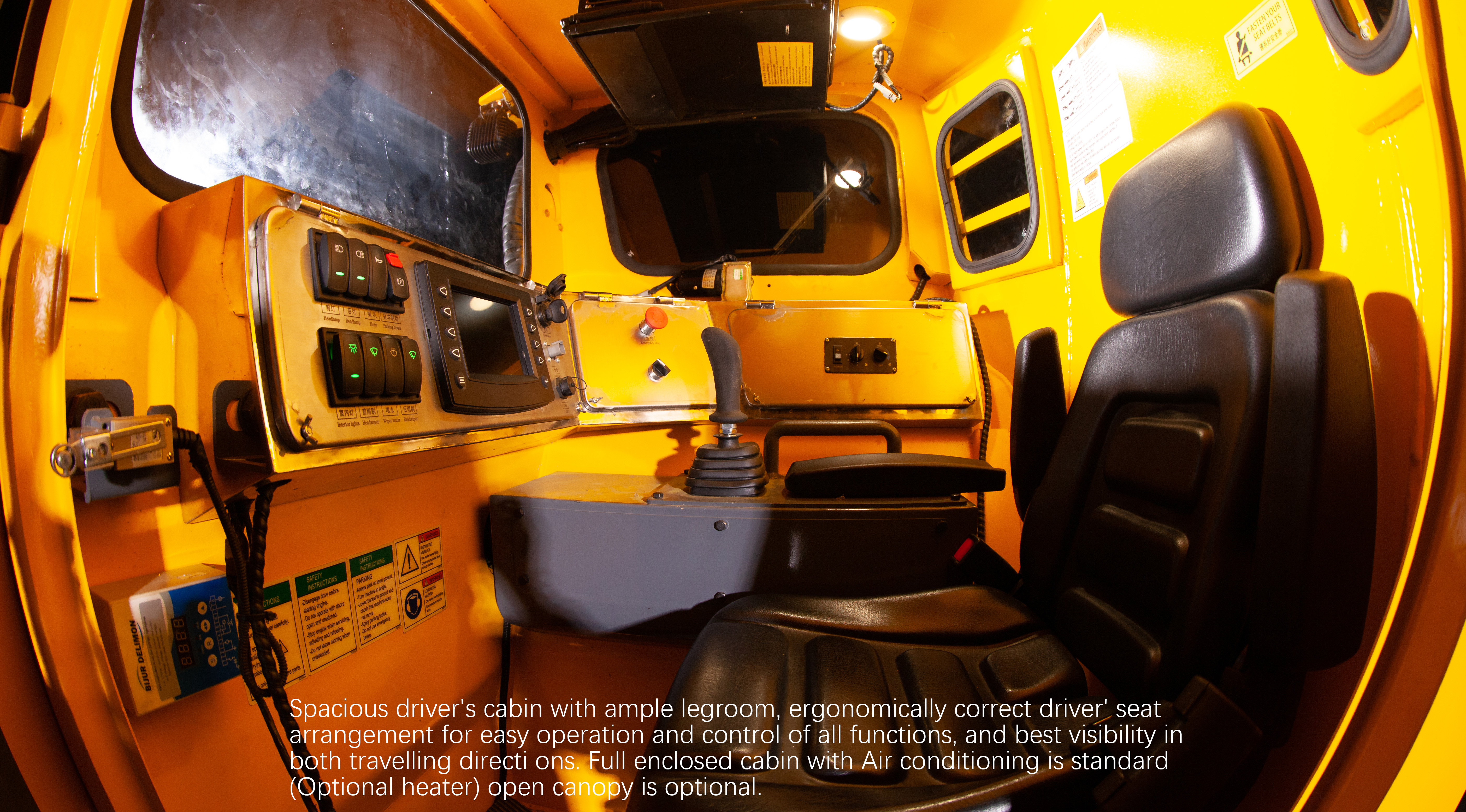

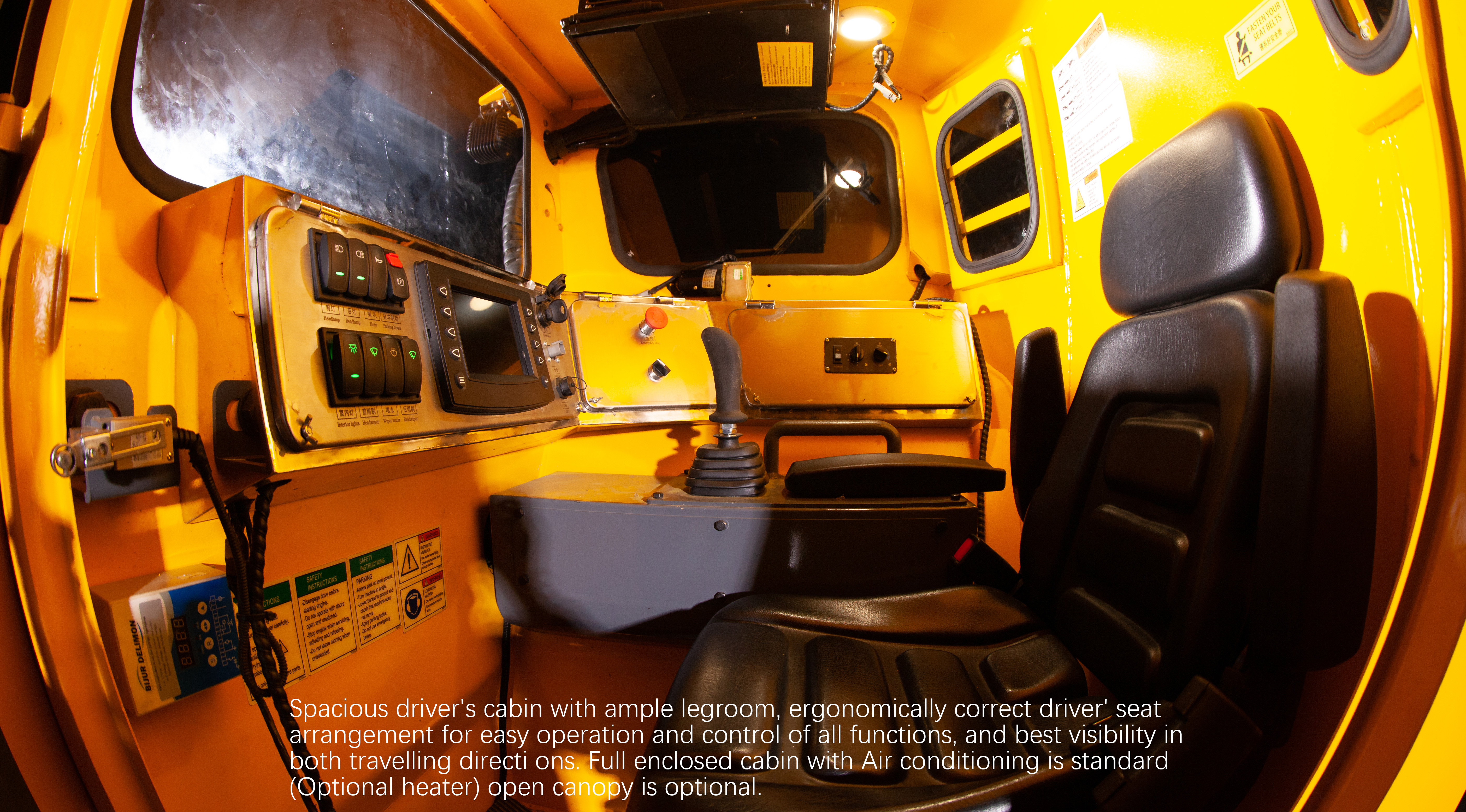

The The DRWJ-3 and DRWJ-3.5 are equipped with the latest safety ROPS/FOPS cabin/canopy. The closed cabin is air-conditioned and noise resistant. It also includes laminated safety glass windows, Large window openings for increased visibility;Large grab handles on both sides to provide 3-point access to cab and machine, anti-slip steps and an emergency exit. The cabin door includes a door lock and latch mechanism with an interlock switch which automatically applies brakes when the door is opened. Controls, levers, switches and gauges positioned to maximize productivity and minimize fatigue.

This loader is fitted with an adjustable low frequency suspension seat with two-point seat belt as standard. Padded arm rests and adjustable joysticks can be configured to suit the operator. The electro-hydraulic joystick controls for steering and boom movements eliminate hydraulic hoses inside the operator’s compartment and reduce potential hydraulic hazards.

Service brakes are spring applied; hydraulically operated multidisc wet

brakes on all wheels. Two independent circuits: one for the front and

one for the rear axle. Service brakes also function as an emergency and

parking brake. Four corner oil-cooled braking system provides excellent

control.This system assures braking in the event of loss of hydraulic

failure.

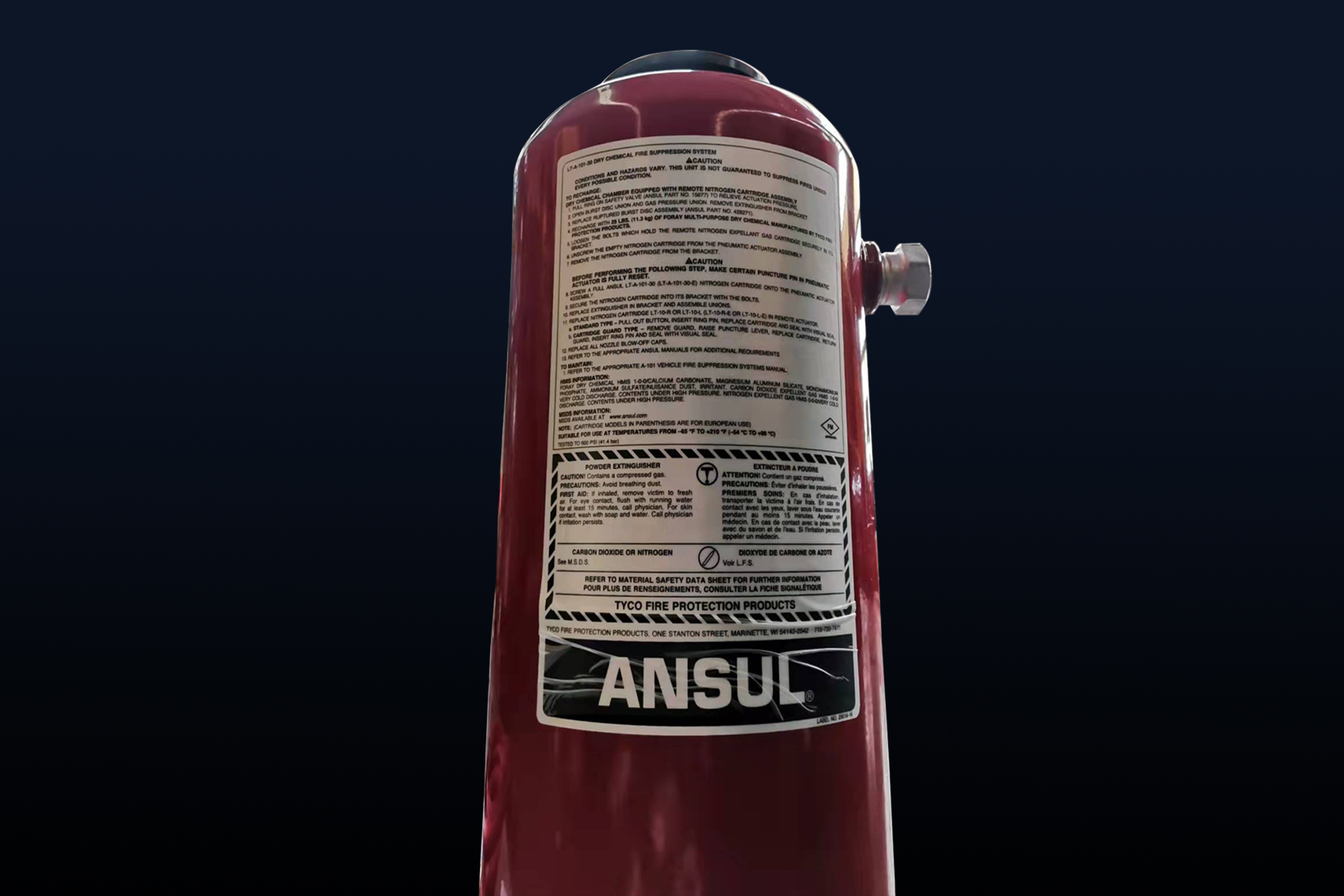

Two emergency stop buttons on the left and right sides of

the rear of the equipment, and one emergency stop button inside the

cabin. Wheel chocks and brackets are optional.

Designed for quick and easy servicing. Simplified service and

maintenance features reduce downtime, allowing the machine to spend less

time being serviced and more time being productive.Thanks to an easily

serviced machine – easy access to all daily service points, saving time,

reducing cost of operation and improving the service life.

The control panel for the DRWJ-3 is designed to be easy-to-use and

informative. All the data and information your operators need to

perform, such as auto-generated diagnostic measurements, adjustments,

and live data readouts, is readily accessible on a sleek control panel.

The

Murphy PV780 is a 7-inch full-color LCD display with IP69

waterproof grade standard. The world's leading LCD technology

makes PV780 clearly visible under direct sunlight. The Murphy

PV780 LCD display is durable in harsh environments. Compatible

with Euro IV emission standards and support multiple languages.

Views of DERUI DRWJ-3 at the mine site