Electric Motor: China top brand, 37KW/50Hz

Drive Train: DANFOSS or LINDE hydrostatic pump&motor

Axle: DERUI OEM brand, made in China

Brake: SAHR through the hydrostatic transmission

Customized buckets optimized for hard rock available

Side tipping bucket: Optional

Top brands hydraulic components: Famous name brands

The Electric Motor

The Electric Motor

Top Hydrostatic Components

Top Hydrostatic Components

Heavy -Duty Designed OEM Axle

Heavy -Duty Designed OEM Axle

Ergonomic operator seat with seat belt

Simple single-pass loading improves productivity

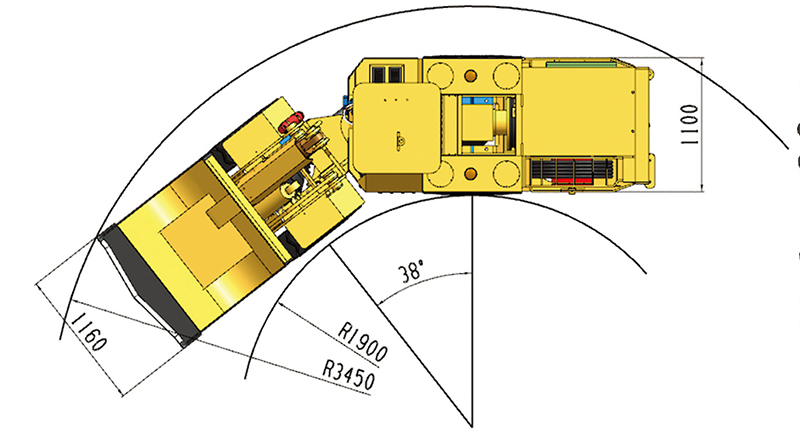

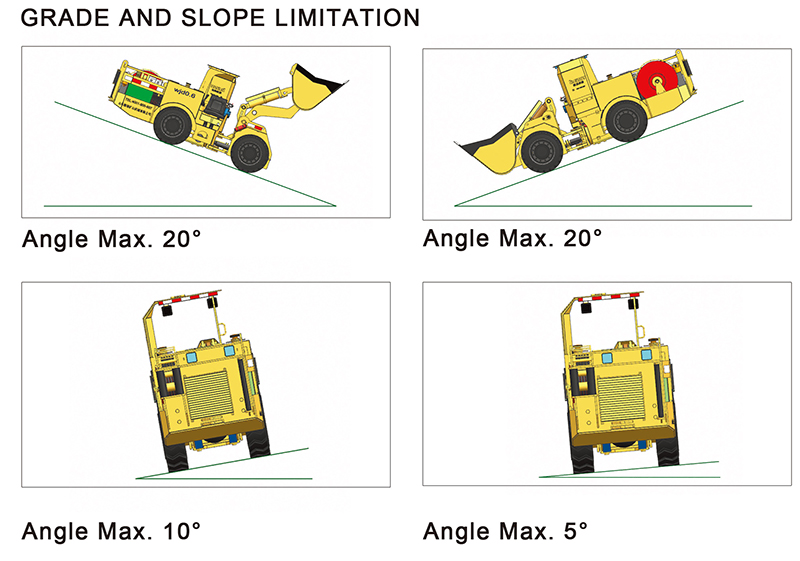

Outstanding manoeuvrability is achieved by the excellent steering angle of the robust articulation joint which allows oscillation of the frame to balance undulating roadways. This layout results in optimum weight distribution on all four wheel and the rear frame is protected against torsional force.

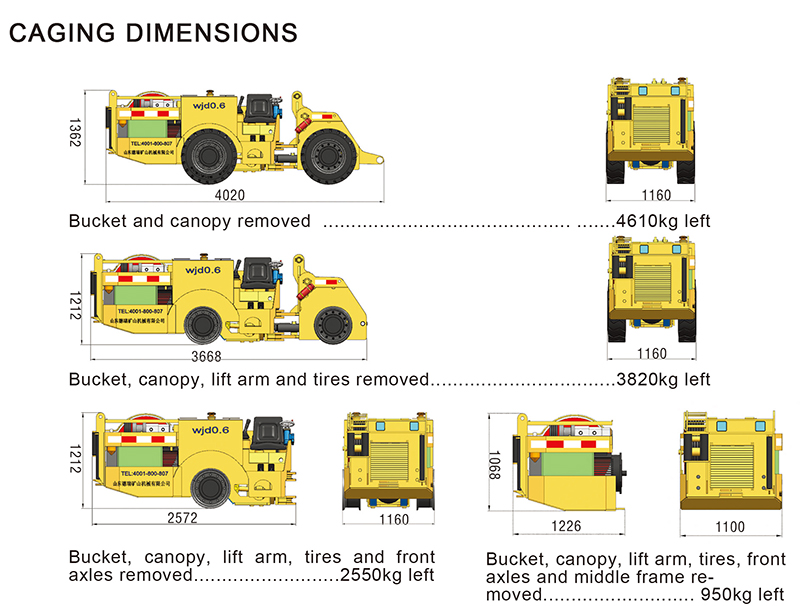

Small envelope size and turning radius enable easy navigation in narrow veins

Low operating weight reduces fuel consumption and extends tire life

Easy access to well-protected service points facilitates daily maintenance

All the service points are well protected but easy to access.

New strengthened cable with automatic tensioning cable reel is more wearable and extend service life.